You need to keep your carburetors synchronized

Is the performance of your old motorcycle or other multi-carburetor engine lagging? Synchronize the carburetors regularly so the cylinders aren’t working against each other.

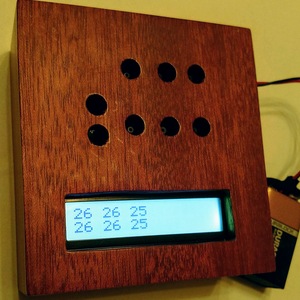

Are you tired of the mess and fuss of oil-filled plastic tubes? Mercury manometers are great if you have one, but they are fragile, toxic, and no longer available for purchase.

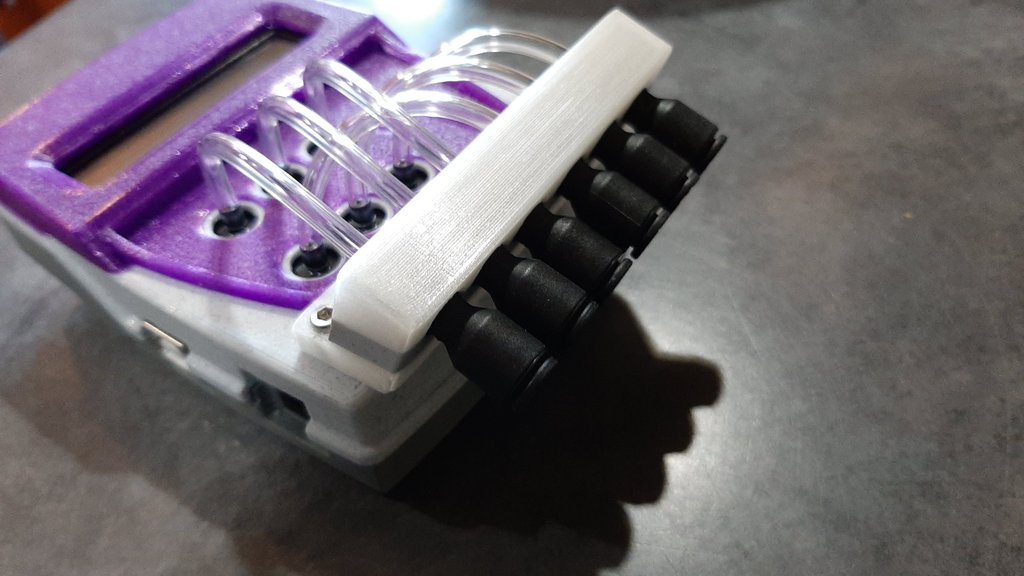

Digital is portable and clean

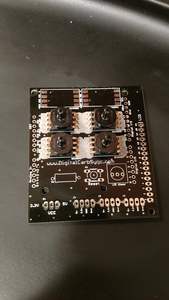

Digital units are lightweight and portable. Unfortunately, most are made for 2-cylinder engines. The Grok Harmonizer is an example. If you have a 4-carb performance bike, something like a 6-carb Valkyrie, an old Kawasaki Z1300, or a Honda CBX1000, things are more difficult and more expensive. Here’s a new and very expensive (~$350) example that only gets you 4 cylinders. One of our customers built two to use on his 12-cylinder airplane engine. Each channel operates independently, so there is no limit.

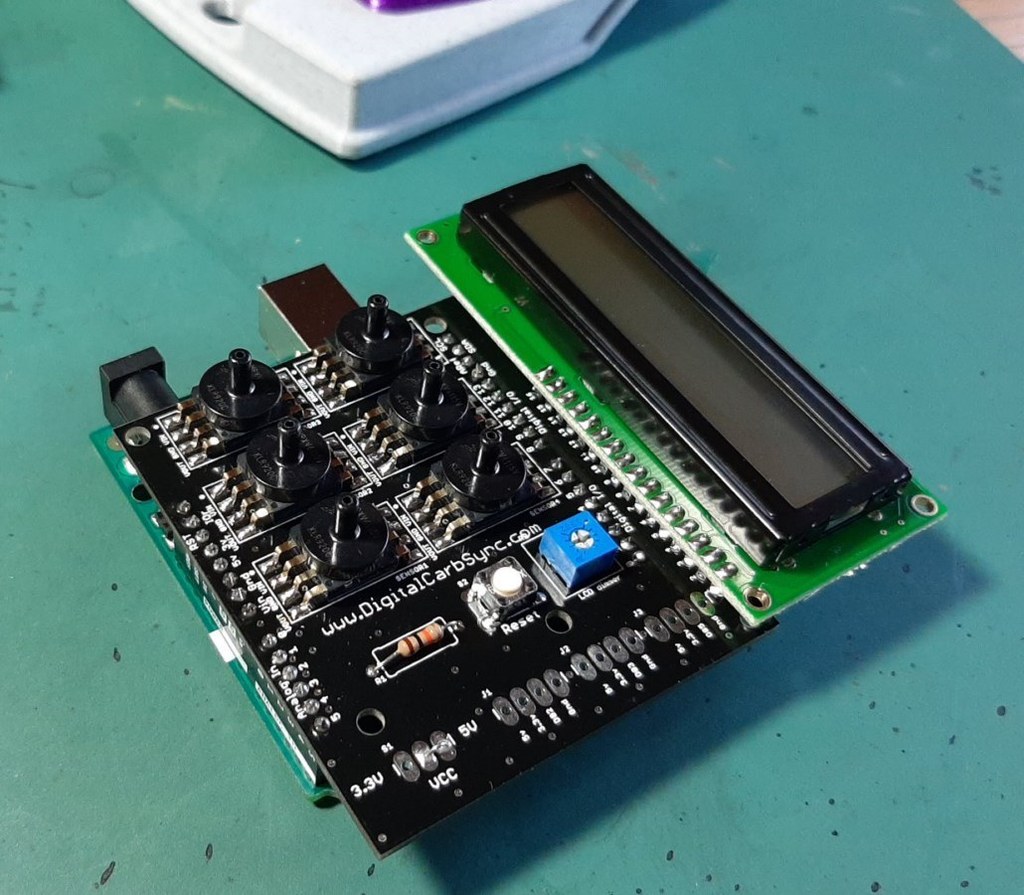

Building your own tools is real

If you have basic shop skills and tools you can build the Digital Carb Sync in a couple of hours. Simple parts and basic soldering are all you need. Loading the software is easy, and the source code is available for people with some beginning code skills who want to make changes.

Digital Carb Sync kits are easy to build

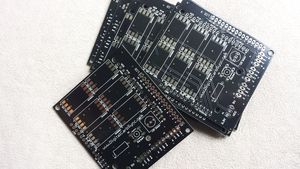

Digital Carb Sync is the original design and kit that makes it easy to build your own digital carb sync tool. Get that bike running at its best. To get started, download the build package—our other items are for convenience. Our Black Label boards are lead-free, can be shipped anywhere, and will save you time.

Please note: If you order a product or contact us, please check your spam folder. Depending on your email service, we automatically set our outgoing email to quarantine until you approve.